Throughout history, humans have endeavored to build magnificent structures that push the limits of what was thought to be possible. The Egyptians built the Great Pyramids, the Greeks built the Colossus of Rhodes, and the Chinese built the Great Wall. Each of these structures, and their counterparts throughout the world, are marvels of beauty and engineering excellence. But we often take for granted the portions of these structures that we do not see – the foundations. Generally, nobody takes notice of the foundations unless something goes wrong. Would the Leaning Tower of Pisa be famous if the foundations did not experience differential settlement? And how is it that more structures have not suffered a similar (or worse) fate?

Let’s explore the topic of ground improvement in more depth, looking at why it’s important and how various ground modification techniques work. Want to navigate to a particular section? Use the jump links below:

What is ground improvement?

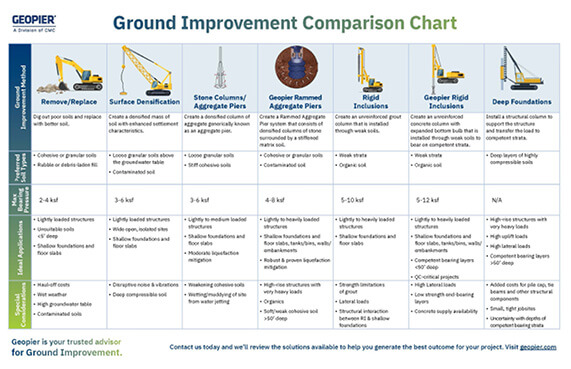

Ground Improvement is the process of modifying or stabilizing soil so that it can be competent to support the loading conditions of the structure being built on top. Inaction could lead to unfavorable consequences, such as excessive settlements or even structural failure.

As the industry leader in ground improvement, Geopier specializes in aggregate piers, rigid inclusions, slope reinforcement and railway subgrade improvement systems. What started as one aggregate pier system in 1989 has expanded over the past 30 years into an arsenal of aggregate pier, rigid inclusion, and densification solutions, including geo-products specifically developed for slope stabilization and railroad track remediation.

Why is ground modification necessary?

Simply stated, not every project site is underlain by competent bearing soils. Sites with poor soils need ground modification to change the conditions so that it becomes suitable to deliver better performance relative to project needs. Poor soils typically consist of loose sands, soft clays, organic soils, and undocumented fill soils. Even stiff clays and dense sands can be problematic for heavily loaded structures. The Geotechnical Engineer will work with the Structural Engineer and the rest of the project team to evaluate the various foundation solutions for support of the proposed structure and recommend cost-effective ground treatment services and systems.

Ground improvement has many benefits including:

- Increased bearing capacity

- Decreased settlement

- Liquefaction mitigation

- Foundation stability

- Minimal spoil

- Less invasive/disruptive

Geopier Impact® System in action

What are some ground improvement methods?

Ground modification encompasses a broad swath of remedial measures, but in general, the concepts mostly revolve around improving soils in place using mechanical or chemical means. A few variations are outlined below.

Surface densification

This consists of using specialized machinery to impart energy into poor soils to densify the material in place. The depth and magnitude of ground modification needed depends on the soil type and the amount of energy imparted into the soil. The end result is a densified mass of soil with enhanced settlement characteristics. Common surface densification methods include heavy surface compaction, rapid impact compaction (RIC), and deep dynamic compaction (DDC). If schedule allows, consideration can also be given to preloading the site with a large mound of soil to induce settlement of the poor soils.

Surface densification works by creating a densified mass of soil which enhances the settlement characteristics

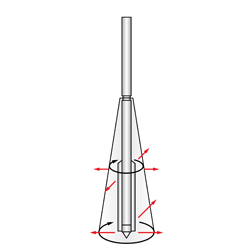

Aggregate piers

Poor soils can be reinforced by replacing/displacing the weaker soils with a densified column of aggregate generically known as an aggregate pier. In this ground improvement process, aggregate pier elements penetrate weak soils to create dense columns of aggregate surrounded by a soil matrix. The matrix soils adjacent to the piers are also densified during pier installation. The end result is an improved mass of soil with enhanced settlement characteristics. Common types of aggregate piers include traditional vibratory stone columns and Geopier’s proprietary Rammed Aggregate Pier® solutions.

Aggregate piers work by creating a rammed aggregate pier system that consists of densified columns of stone surrounded by a stiffened matrix soil

Rigid inclusions

Rigid inclusion ground improvement serves as somewhat of a hybrid between aggregate piers and deep foundations. Rigid inclusions are generally very stiff, cementitious elements that transfer structural loads through weak soil layers and into competent bearing soils (much like a deep foundation). Rigid inclusions are installed by either drilling through or displacing the existing weak soils. The cemented nature of the rigid inclusion elements provides confinement and prevents bulging of the element into weak soils. This is particularly important for very soft clay and organic soil profiles. Rigid inclusions differ from deep foundations in that they are not structurally connected to the overlying foundation. Rigid inclusions are overlain by a gravel pad or load transfer platform and the footing and/or slab is designed as a conventional spread footing and/or slab-on-grade.

.png)

Rigid inclusions work by creating a unreinforced grout column that is installed through weak soils

Soil mixing/grouting

Poor soils can be improved in place by mixing in admixtures such as lime or cement to create a mass with improved engineering properties. This is generally done by mechanically mixing the admixture directly into the soil. Grout can also be introduced to the soil mass to improve the engineering properties, typically by means such as permeation grouting, jet grouting, or compaction grouting.

.jpg)

Poor soils can be improved in place by mixing in admixtures such as lime or cement

What are some common alternatives to ground improvement?

In situations where modern ground engineering solutions might not be the best fit, traditional ground modification techniques—such as removal and replacement of unsuitable soils or the use of deep foundations—still come into play.

Removal and replacement

The engineering behind removal and replacement has not really changed throughout history. If your site has poor soils, you can simply remove them and replace them with better materials. It really does not get simpler than that, or does it? Certain site conditions can make this option impractical. Poor soils can extend so deep as to make removal and replacement cost-prohibitive or difficult, even with modern equipment. Shallow groundwater can necessitate a dewatering program. Adjacent structures can require protection by underpinning or installing sheeting and shoring. Environmentally impacted soils can greatly increase the cost of haul off and disposal. All of these factors can make removal and replacement a less than favorable solution.

Removal and replacement works by digging out the poor soils and replacing with better soils

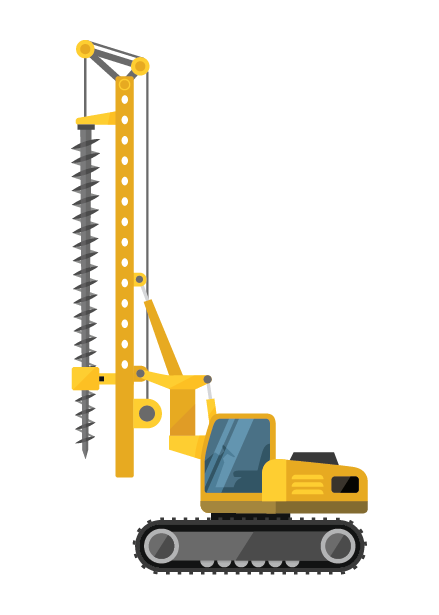

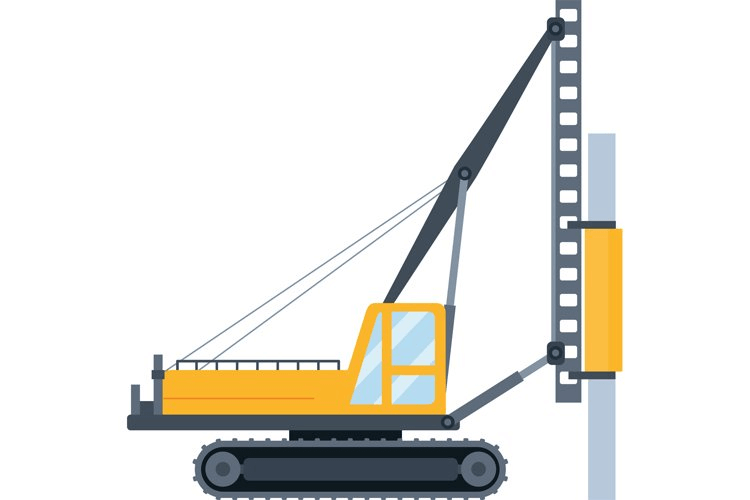

Deep foundations

Deep foundations mitigate the concerns associated with weak bearing soils by bypassing them. The very stiff deep foundation elements take the loads from the structure and transfer them through the weak soils and into suitable bearing soils such as dense sands, hard clays, and bedrock. Modern technology has resulted in many different types of deep foundation options: drilled shafts, driven piles, ACIP piles, and micropiles, to name a few. This geotechnical solution provides excellent settlement control, particularly for heavily loaded structures. However, deep foundations are typically expensive (at least compared to other geotechnical solutions) and require structural slabs, pile caps, and tie beams. In addition, deep foundations generally require several large pieces of equipment on site, which can be problematic on small sites or sites with existing development.

-Construction-machine_.png)

Deep foundations work by installing a structural column to support the structure and transfer the load to competent strata

.jpg)

Geopier's Solutions for Ground Improvement

Rammed Aggregate Pier® systems

Because of their unique construction method, Geopier Rammed Aggregate Pier® (RAP) elements create compaction and stabilization of soil that provide greater capacity than traditional stone columns. Both Geopier RAP elements and traditional stone columns are constructed with sequential lifts of aggregate. However, traditional stone columns are installed using suspended vibratory probes that only deliver horizontal vibration, while Geopier RAP elements are constructed using a beveled tamper to deliver a high magnitude of vertical compaction energy. This results in a stiffer pier as well as significantly increased horizontal stresses and stiffness in the matrix soils. The patented Geopier direct ramming process provides unsurpassed strength and stiffness of the RAP element and matrix soil.

Geopier Rammed Aggregate Pier® systems vs. stone columns

- Greater Capacity: The ramming process produces the superior strength of a Geopier Rammed Aggregate Pier® (RAP) and develops constructed aggregate friction angles greater than 48 degrees, almost 40% greater than those reported for stone columns. Higher friction angles provide greater pier stiffness and capacity, which means fewer Geopier elements versus stone columns.

- Higher Bearing Pressure: Superior pier stiffness delivers higher bearing capacities, which results in smaller footings and lower foundation costs.

- Better Settlement Control: The unique ramming process creates piers that are two to five times stiffer than stone columns. Higher stiffness results in less settlement.

- Versatile: Geopier RAPs can be used for lightly-to heavily-loaded structures.

Customer Success story - Grady Memorial Hospital

Atlanta, Georgia

The ease of construction in a 22-foot deep excavated site made the Geopier GP3® system an attractive value engineering alternative for Grady Memorial Hospital's 16-story structure.

Read more.jpg)

Geopier® rigid inclusion foundation systems

Geopier’s rigid inclusions are comprised of plain concrete, cement-treated aggregate, grout/aggregate mixture, or Armorpact® shells filled with compacted aggregate. Geopier rigid inclusion designs are used to increase bearing capacity (up to 12,000 psf) and minimize total and differential settlements in soft soil profiles, such as peat or organics, soft silt, or soft clay.

Geopier rigid inclusion elements are used to transfer loads through weak, compressible soils and into deeper competent bearing soils. They are ideal for settlement control of heavy structures underlain by thick deposits of compressible soils (organics, soft clays, and loose sands). They can also be used to limit settlement of highly sensitive structures and prevent settlement-related damage to existing structures and utilities.

Customer Success story - College Ave Office Building & Garage

New Haven, Connecticut

Geopier Rammed Aggregate Pier® (RAP) and GeoConcrete® Columns (GCCs) allowed for traditional shallow footings and slab-on-grade construction.

Read more.jpg)

Why Choose Geopier for ground improvement?

Geopier has a solution that can meet your pricing and schedule needs. Our arsenal of patented technologies and services has been successfully used on over 12,000 projects across the globe. With our decades of research and global experience, our company continues to be the innovative leader in geotechnical engineering and technology. Explore our ground improvement solutions today.

Benefits include:

- Foundation improvement techniques suitable for most soil types and structures

- Cost savings of 20 to 50 percent versus deep foundations and removal and replacement

- Conventional spread footing and slab-on-grade design

- Increased allowable bearing pressures (typically 4 to 10 ksf)

- Reduced footing sizes and the associated concrete and steel cost

- Excellent settlement control (total and differential)

- Mitigation of liquefaction-induced settlements

- Increased shear strength to mitigate global stability concerns

- The ability to construct adjacent to existing buildings and utilities

- Minimal spoils/haul-off costs

- Rapid installation reduces construction schedule

Request a complimentary project review to ensure you are maximizing your project’s timeline and budget.

By working with Geopier’s geotechnical engineers to solve your ground improvement challenges, we’ll make sure you achieve the best outcome for your project.

Get in Touch.jpg)