Geopier Rammed Aggregate Pier® Design

Our Rammed Aggregate Pier® (RAP) ground improvement systems consist of densified columns of stone and gravel surrounded by a stiffened matrix soil. These foundation piers are ideal for nearly all soil types and design applications. There are “drill and fill” solutions for non-caving soils (silts and clays) and there are “displacement” solutions for caving soils (sands below the groundwater table) and squeezing soils (soft clays and silts). Our aggregate pier systems can even support structures in organic soils by adding cement or grout (refer to rigid inclusions section). The end result is a stiffened mass of soil that provides improved bearing and excellent settlement control for support of spread footings and slabs-on-grade.

Rammed Aggregate Pier® Systems

There are no results that match your search. Please try another search or Contact Us with further questions.

How Does Geopier's Aggregate Pier Technology Work?

Geopier introduced the Rammed Aggregate Pier® (RAP) technology to the industry in 1989 as an Intermediate Foundation® solution that cost clients 30 to 50 percent less than deep foundations.

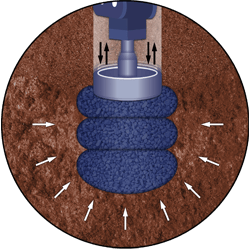

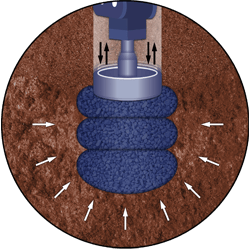

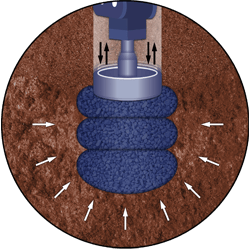

Our foundation pier systems are constructed by applying direct vertical ramming energy to densely compact aggregate to form high-stiffness engineered elements and increase the lateral stress that improves surrounding soils. This process provides superior support capacity, increased bearing pressure (up to 10,000 psf), and greater settlement control for all soil types.

Want Geopier to take a second look at your foundation pier project?

With over 12,000 projects completed, Geopier continues to be the best solution for rammed stone column ground improvement. With decades of research and global experience, our solutions help you save significant cost and time savings across a wide range of applications. We have licensed rammed aggregate pier contractors across the globe. Locate a geotechnical engineer near you to ensure you are maximizing your project's timeline and budget.

Success Stories

PREPA Power Plant

Application: Power and EnergySystem: Geopier Impact® system

Caroline Street Residences

Application: ResidentialSystem: Geopier Impact® system

Moorhead High School

Application: Religious/EducationSystem: Geopier X1® system

How do Geopier's foundation piers compare to the competition?

There are many choices when it comes to aggregate piers, but not all aggregate technologies are created equal. Geopier, with its proprietary Rammed Aggregate Pier® systems, is the gold standard in foundation pier technology, design, engineering, and customer focus.

Stone Columns

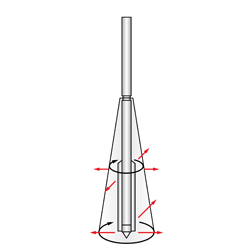

Vibrolflot tooling only provides horizontal vibration, limiting pier stiffness and settlement control.

- Limited pier stiffness for reduced settlement control

- Typical bearing pressures of 3 to 6 ksf

- More piers required, resulting in more time on site

Geopier Rammed Aggregate Pier®

Patented technology provides both vertical and horizontal energy, creating a superior pier element.

- Superior pier stiffness (2x-5x) for excellent settlement control

- Typical bearing pressures of 4 to 8+ ksf

- 20 to 40 percent less piers, resulting in less time on site

Deep Foundations

Deep foundations provide excellent settlement control, but at significant cost and schedule impact.

- Pile caps and structural slabs required

- Slow installation speed and concrete

- Several large pieces of equipment required

Geopier Rammed Aggregate Pier®

Rammed Aggregate Pier technology offer the same settlement performance as deep foundations at a fraction of the cost and schedule.

- Conventional spread footings and slabs-on-grade

- Rapid installation and footing construction

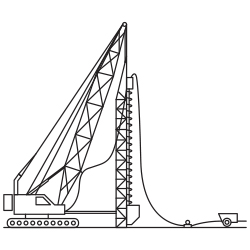

- Minimal equipment and personnel required

Removal and Replacement

Removal and replacement carries a lot of unknown and can be impractical for a multitude of site conditions.

- Typical bearing pressures of 3 to 5 ksf

- Significant spoils and haul-off

- Potential for cost overages and delays due to unknowns and need for shoring, underpinning, dewatering

Geopier Rammed Aggregate Pier®

Geopier Rammed Aggregate Pier elements are generally cost-effective for undercuts greater than 6 feet, shallower for environmentally impacted soils.

- Typical bearing pressures of 4 to 8+ ksf

- Minimal to no spoils and haul-off

- Minimal potential for cost overages and site-related issues/delays

Resources

Proper Load Testing Procedures to Verify Adequate Design of Geopier Supported Foundation Systems

Structural Design Considerations for Uniformly-Loaded Floor Slabs Supported by RAPs

Geopier Rammed Aggregate Pier® Advantage Flyer

Your Regional Sales Manager

Your Inside Sales Manager

Your Local Distributor

There are no results that match your search. Please try another search or Contact Us with further questions.